3D-Printed Solutions for Orthopedic Surgery

At restor3d, we create personalized medical products to improve patient outcomes. By combining 3D printing, biomaterials, and biomechanics, we aim to expand patient-specific musculoskeletal care. Explore our products below.

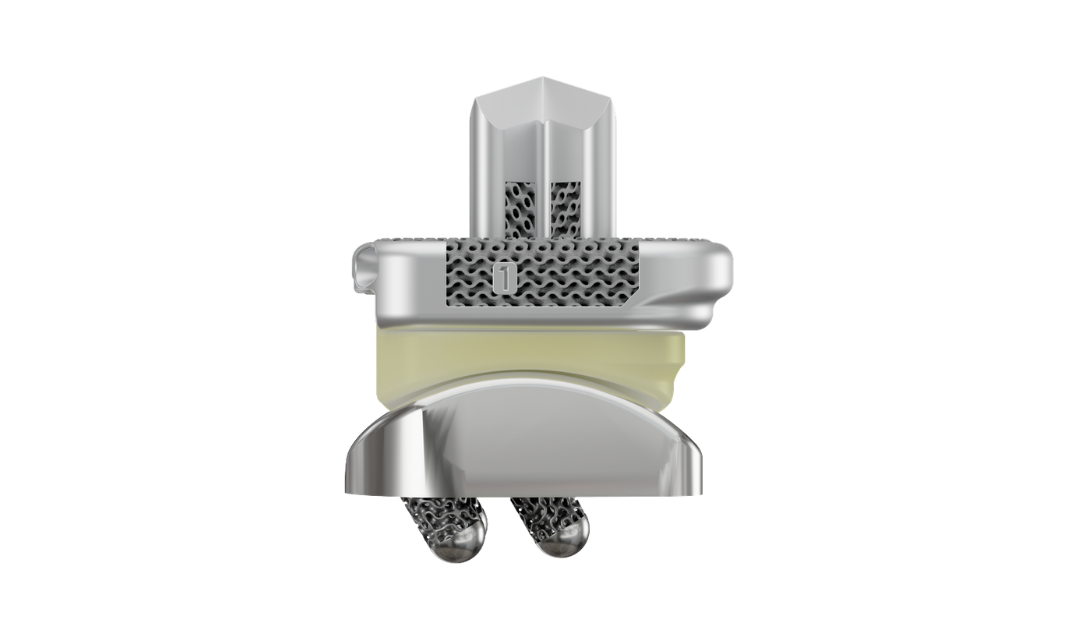

Knee

Explore Products

Personalized joint replacement solutions tailored to your practice needs and your patient’s anatomy.

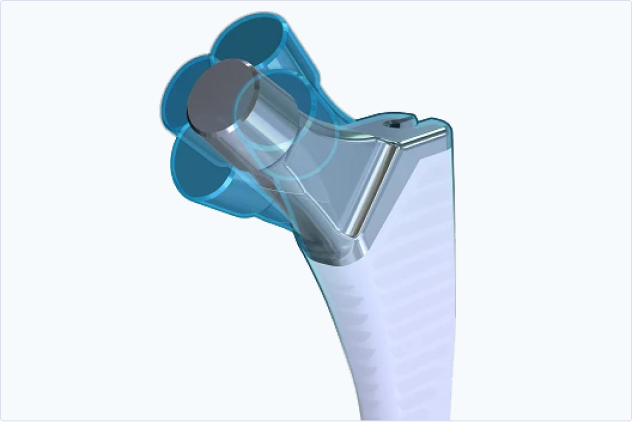

Hip

Explore Products

3D image-to-implant hip replacement system providing intuitive surgical plans and instruments.

Digital Solutions

r3id | Personalized Surgery

Our digital platform allows surgeons to create and track cases efficiently and collaborate with restor3d’s Design Engineering Team to maximize patient-specific surgical outcomes.