Revolutionary Cannulated Bone Screw with Faceted Technology

This Faceted Bone Screw Technology Is Revolutionizing Orthopedic Fixation. Featuring Diamond Orthopedic technology, these faceted screws are the next generation of bone screws in orthopedics. These screws feature facets or 'valleys' on the threads increasing thread volume. This results in better bone engagement and reduced compressive stress.

The thread valleys provide 50% less insertional torque during insertion and hold up to 20% more bone volume. Following insertion, bone relaxes into the facets enabling greater contact compared to regular helical screws.

Peaks

The ‘peaks’ serve as the initial area of bone/screw contact during insertion, which reduces friction and results in ~50% less torque required for insertion.

Valleys

Immediately following insertion, bone relaxes into facet ‘valleys,’ enabling greater bone/screw contact than the typical helical screw

Bone Engagement

Facets bring a “volumetric advantage,” with thread valleys holding up to 20% more bone volume, enabling greater pullout strength and toggle performance.

Insertion: Less Stress on the Bone

The faceted thread's unique design reduces friction during insertion. Facet 'valleys' serve as a bone stress relief mechanism, resulting in ~50% lower insertional torque and less potential for microfractures and necrosis.

Post-Insertion: Bone Engagement

After insertion, the facet "valleys" also promote restoration of bone against the screw flanks, creating a firm grip that increases fixation and retention strength, and reduces post- insertion compressive stress. Faceted screws distribute the load over a greater volume of bone and significantly increase the peak pullout load.

The New Fixation Standard

Rigorous testing conducted at Orthokinetic Testing Technologies demonstrated that faceted screws deliver improved fixation integrity. There is significantly less risk of screw loosening due to cyclic loading compared to the standard helical screw. The faceted screw also provides 61% greater pullout strength within 2 weeks of surgery providing the best fixation for patients.

Ready to Get Started?

Give us a call or talk to a sales agent to find out more about restor3d's state-of the art 3D printed portfolio of revolutionary orthopaedic products, how they will revolutionize orthopaedic surgery for future patients, and to learn more.

Learn More About Our Cannulated Screws

Get in touch for more information about the restor3d's Cannulated Screw, surgical techniques, and sizing options.

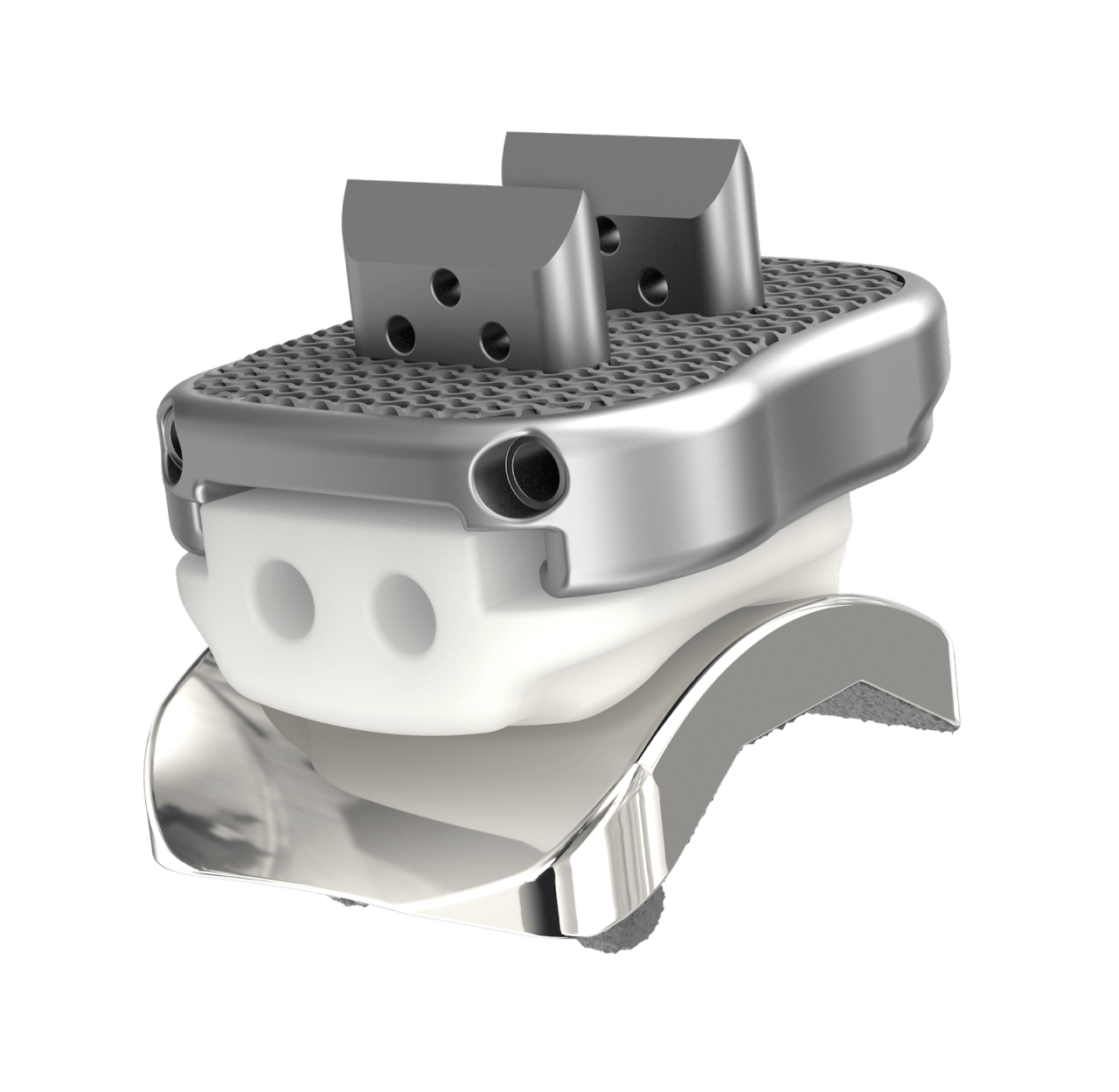

The Benefits of TIDAL Technology™

We're proud to create optimized porous architecture designed for osseointegration with TIDAL Technology™.

100% Interconnectivity and up to 80% porosity

Mesoscale pores support graft retention and bony ingrowth

Direct bony apposition to implant surface guided by surface topography and curvature demonstrated in a preclinical model

Proprietary porous technology encourages better fusion

Expulsion resistance with hierarchical surface topography

Related Products

State-of-the-art technology like diamond ortho screws, osteotomy wedges, Kinos Axiom® Total Ankle Replacement System, osseoREBAR™ nails, and cervical fusion cages create our orthopedic systems. Our products unite 3D printing, biomaterials, biomechanics, and artificial intelligence to offer some of the best implant and fusion solutions in the industry.

Connect with us on LinkedIn

Follow us on LinkedIn to see the latest updates from restor3d.